Description

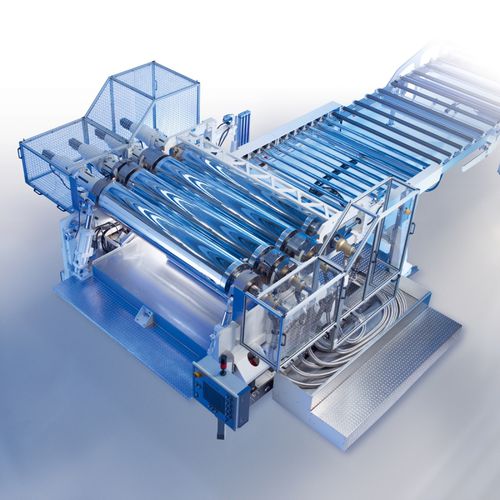

A Calender Machine is a specialized industrial equipment used to process and shape thermoplastic materials, such as PVC, PET, PP, or other polymers, into thin sheets or films with precise thickness, smooth surfaces, and high-quality finishes. This machine is widely utilized in the production of plastic sheets, films, and other flat materials, offering efficient and consistent results for the manufacturing and packaging industries.

Key Features of Calender Machine

- High Precision: Produces uniform plastic sheets or films with exact thickness control.

- Multi-Roll System: Equipped with 3, 4, or 5 rollers for versatile processing capabilities.

- Adjustable Settings: Enables fine-tuning of temperature, pressure, and roller speed for different materials.

- Smooth Surface Finishing: Polishing rollers ensure high gloss and smooth finishes for plastic products.

- High-Speed Operation: Capable of continuous operation to meet high-volume production demands.

- Durable Construction: Made from corrosion-resistant materials to handle high temperatures and pressures.

- User-Friendly Interface: Includes touchscreen control panels for easy operation and monitoring.

- Energy Efficiency: Advanced heating systems minimize energy consumption while maintaining performance.

Applications:

- Plastic Sheet Production: For manufacturing thin, flexible, or rigid plastic sheets used in packaging, construction, or decoration.

- Plastic Film Manufacturing: Creates films for food packaging, medical use, or industrial applications.

- Thermoforming Processes: Produces materials used in making disposable containers, trays, or lids.

- Surface Finishing: Enhances the appearance and texture of plastic materials with smooth or glossy finishes.

Technical Specifications (Example):

- Roller Configuration: 3-roll or 5-roll system

- Material Compatibility: PVC, PET, PP, PS, and other thermoplastics

- Sheet Thickness Range: 0.1mm – 5mm (customizable)

- Roller Temperature Range: Up to 300°C

- Speed: Up to 50m/min (adjustable)

- Power Supply: 220V/380V, 50/60 Hz

- Machine Dimensions: Customizable based on production needs

Calender Machine Advantages:

- Versatility: Suitable for various plastic types and production scales.

- Improved Productivity: High-speed operation and automation reduce downtime and manual labour.

- Customizable Outputs: Adjustable settings ensure flexibility for different product requirements.

- Enhanced Quality: Produces consistent, high-quality sheets and films with smooth surfaces.

Plastic Calendering Process

The plastic calendering process is a manufacturing technique used to produce thin PVC plastic sheets calendaring, films, or coatings by passing molten or semi-molten plastic through a series of heated rollers. This process ensures the material achieves the desired thickness, surface texture, and finish, making it ideal for applications requiring precision and smoothness.

Steps in the Plastic Calendering Process:

- Material Preparation:

- Heat melts or softens thermoplastic materials like PVC, PET, PP, or PS. Manufacturers mix additives like colourants, stabilizers, or plasticizers to enhance properties.

- Feeding into Rollers:

- A multi-roll calendering machine, typically with 3, 4, or 5 heated rollers arranged in a stack or inline, feeds the softened material.

- Compression and Shaping:

- The rollers compress and stretch the material to achieve the desired thickness and width, with the gap between them determining the sheet or film thickness.

- Polishing and Surface Finishing:

- Polishing rollers smooth the surface or create a high-gloss finish. Alternatively, embossing rollers can add textures or patterns.

- Cooling and Solidification:

- The processed sheet or film is cooled using chill rollers or air-cooling systems to solidify the material and stabilize its shape.

- Trimming and Cutting:

- Edges of the sheet are trimmed for uniformity, and the material is cut or wound into rolls for storage or further processing.

Calendar Machine price in Bangladesh

The price of calendar machines in Bangladesh varies significantly depending on the type, size, capacity, and specific application (e.g., plastic, paper, or textiles). Calendering machine cost it is recommended to contact us for specific pricing as prices may vary based on shipping, customization, and additional features.

The calendering machine is an indispensable tool for manufacturers aiming for high efficiency, precision, and quality in plastic sheet and film production. With its advanced features and robust design, it meets the demands of modern production environments.

Reviews

There are no reviews yet.