Description

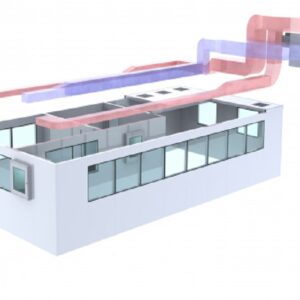

Safe and Effective Industrial Water Pipeline Installation

Our Safe and Effective Industrial Water Pipeline Installation service ensures optimal water distribution for your industrial facility. We design and install durable pipelines using high-quality materials and state-of-the-art equipment. Our team follows strict safety protocols and industry standards to deliver installations that minimize risks and maximize efficiency. We handle every step, including planning, pipe routing, welding, and pressure testing, to guarantee a seamless system that meets performance and regulatory requirements. Trust our expertise to build a reliable, long-lasting water infrastructure tailored to your operational needs, ensuring smooth and continuous water flow.

Industrial Water Pipeline Materials and Equipment

Materials:

- PVC (Polyvinyl Chloride) – Lightweight, corrosion-resistant, and cost-effective for low-pressure applications.

- HDPE (High-Density Polyethylene) – Durable, flexible, and resistant to chemicals and corrosion, suitable for medium to high-pressure use.

- Stainless Steel – High strength, corrosion resistance, and long lifespan, ideal for high-pressure and sanitary applications.

- Carbon Steel – Strong and durable, used for high-pressure systems but may require coatings for corrosion resistance.

- Copper – Highly resistant to corrosion and suitable for smaller-scale or specialized applications.

- Ductile Iron – Strong, durable, and suitable for large-scale industrial applications.

Equipment:

- Pipe Laying Machines – Used for efficient and precise pipe placement.

- Trenchers and Excavators – For digging trenches to lay the pipelines.

- Welding Equipment – For joining metal pipes (e.g., arc welders, fusion welding tools).

- Pipe Fittings – Includes elbows, tees, couplings, and flanges for connecting and redirecting pipes.

- Joint Sealing Materials – Such as gaskets and sealants to ensure leak-proof connections.

- Pressure Testing Equipment – To check for leaks and verify the integrity of the system.

- Pipe Cutters and Benders – For cutting and shaping pipes to fit the layout.

- Surveying and Alignment Tools – To ensure accurate placement and alignment of pipes.

- Hydraulic and Mechanical Lifting Equipment – For positioning heavy pipes and components.

Professional Laying of Water Supply Pipes for Reliable Water Distribution

Laying of Water Supply Pipes involves installing pipelines to create an efficient water distribution network. This includes site assessment, trenching, pipe placement, and secure connections using durable materials like PVC, HDPE, and steel. Proper installation methods ensure compliance with safety standards and maintain system integrity. Expert teams conduct thorough testing for performance and leak-free operation, providing a reliable, long-lasting water supply solution for various needs.

Reviews

There are no reviews yet.