Description

New Project Machinery Installations Steps

This document outlines the planning, execution, and commissioning of machinery installations for the new project. It is a guideline for stakeholders, project managers, engineers, and contractors involved in the installation process.

Objectives

- Ensure safe and efficient installation of machinery.

- Minimize downtime during installation.

- Comply with all safety and regulatory standards.

- Integrate machinery with existing infrastructure and processes.

Pre-Installation Requirements

Safety Considerations

- Adhere to all OSHA and local safety regulations.

- Use personal protective equipment (PPE) at all times.

- Perform risk assessments before and during installation.

Post-Installation Actions

- Schedule regular maintenance to ensure optimal performance.

- Monitor machinery for initial operational issues.

- Update operational procedures to include new machinery.

Documentation

- Maintain records of installation, testing, and calibration.

- Include equipment manuals, safety guidelines, and inspection reports in the project documentation.

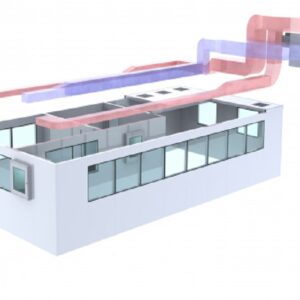

Solutions for heavy New project machinery installations

Our heavy machinery installation solutions deliver efficient, comprehensive services for large-scale projects. We handle every phase—from site preparation and equipment transport to precise assembly—with expert planning and execution. Prioritizing safety, reliability, and minimal downtime, we use advanced tools to ensure timely, budget-friendly completion. Committed to quality and precision, we support industries needing robust machinery setups for optimal performance and long-term success.

Responsibilities of an Appliance and Equipment Installer

The responsibilities of an appliance and equipment installer include:

- Installation and Setup: Ensuring proper installation and setup of various appliances and equipment according to manufacturer specifications and safety guidelines.

- Inspection and Testing: Conduct thorough inspections and tests to confirm that the installed appliances and equipment function correctly and meet operational standards.

- Technical Troubleshooting: Diagnosing and resolving any issues that may arise during or after the installation process to ensure optimal performance.

- Customer Interaction: Providing clear instructions and guidance to clients on how to use, maintain, and troubleshoot their appliances and equipment.

- Compliance and Safety: Adhering to local codes, safety regulations, and industry standards during the installation process to ensure a safe working environment.

- Equipment Transport: Managing the transportation and handling of heavy equipment and appliances to and from job sites.

- Documentation and Reporting: Maintaining accurate records of installation work, service reports, and warranty information for customers and company use.

- Maintenance Services: Performing routine maintenance or repair services on appliances and equipment as needed.

- Collaboration: Working with other team members or specialists to coordinate larger installations or projects that require multiple skills or expertise.

- Training and Knowledge Update: Keeping up-to-date with new technology, installation practices, and manufacturer guidelines to stay current in the field.

Contact Information

121/6, Surtorongo Road, Auchpara, Nishatnogor, Tongi-1711, Gazipur, Dhaka-Bangladesh.

E-mail: info@quantechbd.com Or sales1@quantechbd.com

Hotline Number: +88 01327 140 075

Reviews

There are no reviews yet.