Description

Expert Clean Room Installation for Optimal Facility Performance

Clean Room Installation Details:

Clean room installation involves the design, construction, and setup of controlled environments that meet strict cleanliness and operational standards. These rooms are essential for industries such as pharmaceuticals, biotechnology, electronics, and laboratories where contamination must be minimized to ensure product quality and safety.

Key Components of Clean Room Installation:

- Design and Planning: Customized design based on industry-specific requirements and compliance standards such as ISO 14644. This includes planning for room layout, airflow, and accessibility.

- Construction and Build: Utilizes high-quality materials to create airtight and smooth surfaces that are easy to clean. Installation includes modular walls, ceiling panels, flooring, and proper sealing to prevent contamination.

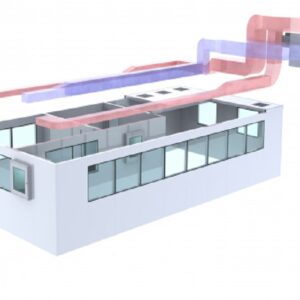

- HVAC Systems: Installation of advanced HVAC systems with HEPA or ULPA filters to control temperature, humidity, and particle levels, ensuring a consistent and contaminant-free environment.

- Airflow Control: The setup of a controlled airflow system to maintain laminar flow and reduce the risk of particle contamination.

- Lighting and Power Supply: Proper lighting installation to maintain visibility without compromising cleanliness, along with a reliable power supply for equipment and machinery.

- Clean Room Equipment: Installation of necessary equipment like clean room benches, storage, and gowning areas, ensuring all items are easy to disinfect and maintain.

- Monitoring and Compliance: Integration of monitoring systems for real-time control of particle counts, temperature, and humidity to ensure adherence to ISO and GMP standards.

- Testing and Certification: Conducting thorough validation and testing to certify that the clean room meets all operational standards. This includes air quality tests, particle count verification, and system performance checks.

Benefits

- Regulatory Compliance: Meets stringent industry standards to pass audits and inspections.

- Improved Efficiency: Optimized workflow and operational efficiency.

- Enhanced Safety: Reduces the risk of contamination, ensuring a safer environment for products and workers.

- Custom Solutions: Tailored to specific needs, ensuring the clean room meets unique operational requirements.

- Long-Term Durability: Built to last with high-quality materials and systems that require minimal maintenance.

Here’s a Chart Summarizing the Technical Specifications

| Category | Details |

|---|---|

| Class & Standards | ISO Class 1-9, GMP, Federal Standard 209E (US) |

| Structure | Walls: Non-porous (e.g., vinyl-coated gypsum, stainless steel); Ceilings: High-efficiency filters; Flooring: Seamless, anti-static; Doors/Windows: Air-tight. |

| HVAC System | HEPA/ULPA filters, 20-60 ACH, 18-24°C temperature, 40-60% RH humidity, positive pressure. |

| Lighting | LED/fluorescent, 300-1000 lux, easy-to-clean fixtures. |

| Equipment & Furniture | Stainless steel workbenches, cleanroom-grade storage, air showers for decontamination. |

| Monitoring | Real-time particle counters, temperature/humidity sensors, and alarms for deviations. |

| Access Control | Electronic access, biometrics, RFID, interlocking doors. |

| Clean Room Clothing | Full PPE including suits, gloves, masks, hair/foot covers; strict gowning procedures. |

| Utility Systems | Ultra-pure water, dedicated waste systems. |

| Testing & Validation | Initial and ongoing particle count, airflow, pressure tests; ISO/GMP certification. |

This summary covers the key aspects of clean room specifications, ensuring essential features and standards are met.

Conclusion: Professional clean room installation ensures that businesses have reliable, efficient, and compliant environments essential for high-quality production and research.

Reviews

There are no reviews yet.