Description

Plastics Auxiliary Machinery: Best Efficiency in Plastic Processing

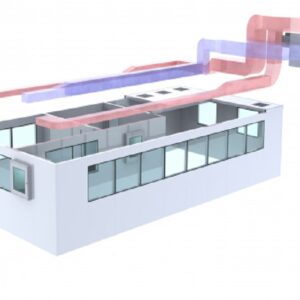

Plastics auxiliary machinery play a critical role in ensuring the smooth operation and efficiency of the plastic processing industry. These auxiliary machines support primary production equipment by managing essential tasks like drying, temperature control, material feeding, and recycling. Whether it’s an injection molding machine or extrusion processes, auxiliary equipment ensures optimal quality and productivity.

Features of Plastics Auxiliary Machinery

-

Advanced Control Systems

- User-friendly interfaces for precise operation and monitoring.

- Automated settings for consistent performance.

-

Energy Efficiency

- Low power consumption to reduce operational costs.

- Eco-friendly designs that minimize environmental impact.

-

High Precision and Reliability

- Accurate temperature and material flow control for quality production.

- Durable construction for long-term, trouble-free operation.

-

Versatility and Compatibility

- Can handle various materials and integrate seamlessly with primary machinery.

- Adaptable to different production needs and scales.

-

Automation Capabilities

- Robotic arms and automated feeders for improved efficiency.

- Reduced manual labour and enhanced safety.

-

Recycling and Waste Management

- Granulators and shredders for efficient recycling of plastic waste.

- Helps reduce material costs and supports sustainable practices.

-

Customizable Options

- Tailored solutions for specific production processes.

- Flexible configurations to meet unique operational requirements.

These features contribute to higher productivity, cost savings, and a more sustainable approach in the plastic processing industry.

Why Choose Plastic Machinery in Bangladesh?

- Affordable Solutions: Bangladesh-based suppliers provide cost-effective auxiliary equipment for SMEs and large factories.

- Wide Range of Products: From plastic grinders to chillers and recycling units, the market meets diverse needs.

- Growing Industrial Zones: Increasing demand in Dhaka, Chittagong, and beyond offers opportunities for scalable growth.

- Repair and Maintenance Services: Local repair services ensure smooth, continuous operations.

Types of Auxiliary Machinery Available

- Material Dryers

- Mold Temperature Controllers

- Chillers

- Mixers

- Recycling Machines

Investing in plastic auxiliary machinery is vital for efficient, cost-effective, and sustainable production in Bangladesh. The right equipment, such as dryers, chillers, or recycling units, can greatly enhance production quality and output for manufacturers of all scales.

Benefits

Plastic auxiliary machinery plays a crucial role in improving the efficiency and effectiveness of plastic manufacturing processes. Here are the key benefits:

-

Enhanced Productivity

- Speeds up production by automating material handling and processing tasks.

- Reduces downtime with efficient operations and quick changeovers.

-

Improved Product Quality

- Ensures consistent material properties through precise drying, blending, and temperature control.

- Reduces defects in final products by maintaining optimal processing conditions.

-

Cost Efficiency

- Minimizes material waste through recycling and reprocessing systems like granulators and shredders.

- Optimizes energy usage with advanced temperature control and efficient drying systems.

-

Operational Flexibility

- Accommodates a variety of materials and production requirements.

- Easily integrates with primary processing equipment, enabling scalability.

-

Sustainability

- Promotes recycling and reuse of plastic waste, reducing environmental impact.

- Supports sustainable practices through energy-efficient designs.

-

Automation and Safety

- Automates labour-intensive tasks, reducing manual intervention.

- Improves workplace safety by limiting human exposure to hazardous environments.

If you need further assistance in selecting the right machinery or have questions about installation and maintenance, feel free to contact us!

Reviews

There are no reviews yet.